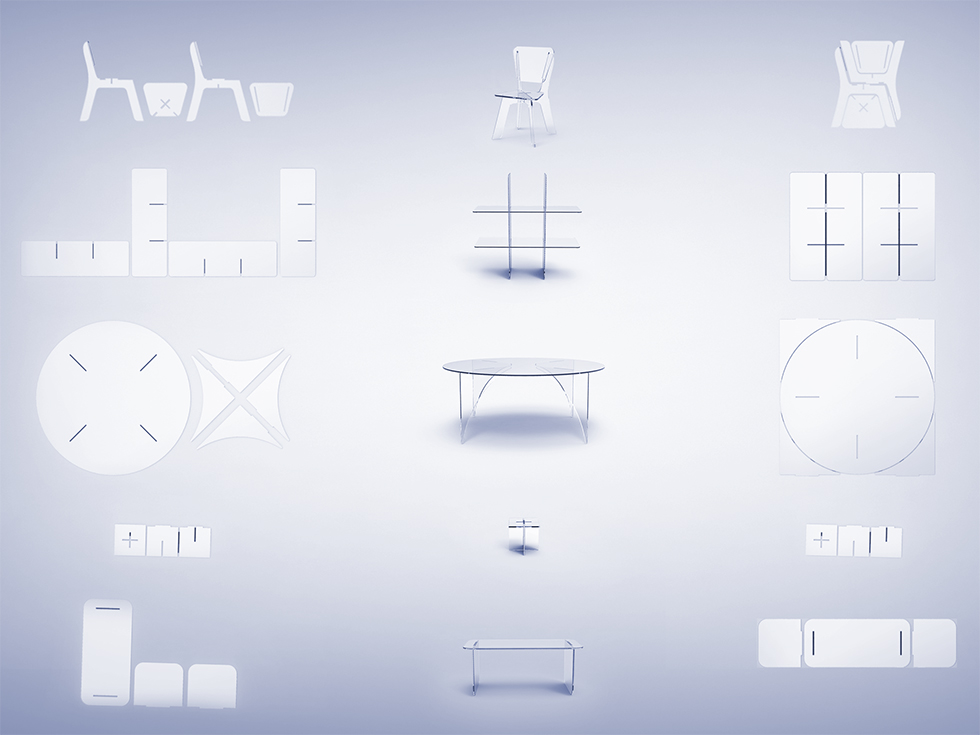

Oxi-gen is a case study focused on production simplicity, efficiency and transport.

Different panel materials can be produced with different CNC production processes for easy transport, assembly and disassembly without tools.

Design itself is suitable for exhibitions, fairs and presentations as it is very customizable and compact to transport when disassembled.

Produced at very low tolerances all furniture pieces should stick together firmly after the assembly.

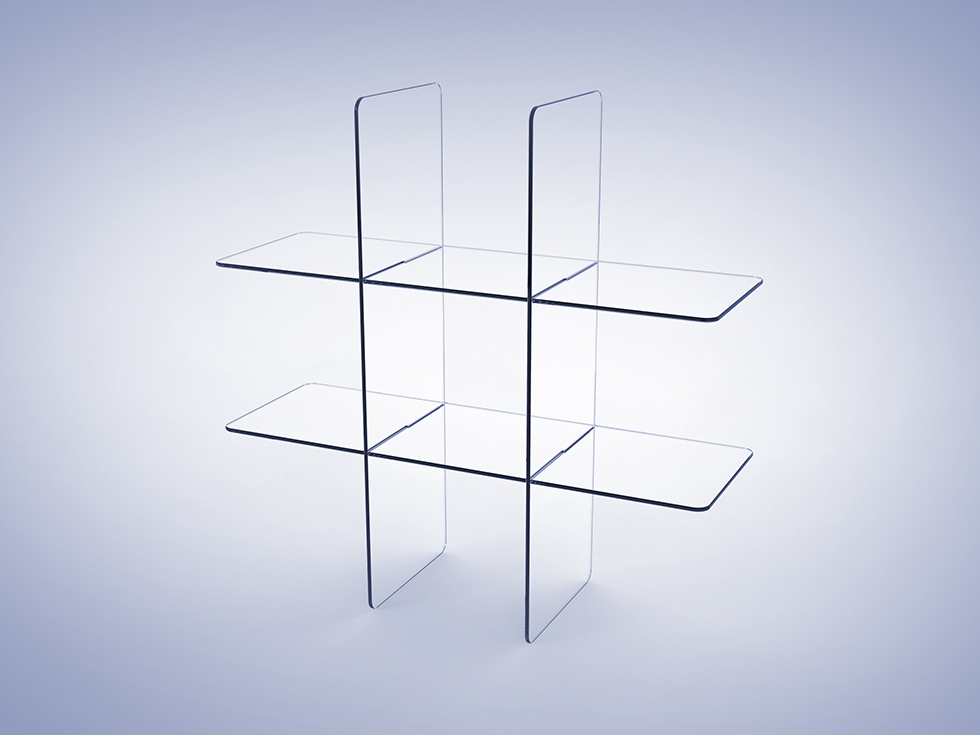

Design pieces featured here are displayed in transparent material to highlight its geometry and simplicity.

Different panel materials can be produced with different CNC production processes for easy transport, assembly and disassembly without tools.

Design itself is suitable for exhibitions, fairs and presentations as it is very customizable and compact to transport when disassembled.

Produced at very low tolerances all furniture pieces should stick together firmly after the assembly.

Design pieces featured here are displayed in transparent material to highlight its geometry and simplicity.

Name of each piece is just combination of its parts. Here are displayed their names, assembled furniture and their parts cut out from single panel which minimizes production costs by reducing waste at the same time:

Oxi-gen collection was developed by using DFS (Design for Sustainability) principles.

By using single material and production technique the furniture here is 100% recyclable with production waste that is less than 1% but also recyclable without any toxic or hazardous waste being made.

With package made of recycled cardboard the design tops the environmental production and design index.

Design, modeling, digital renderings and post-production by Darko Nikolić

By using single material and production technique the furniture here is 100% recyclable with production waste that is less than 1% but also recyclable without any toxic or hazardous waste being made.

With package made of recycled cardboard the design tops the environmental production and design index.

Design, modeling, digital renderings and post-production by Darko Nikolić